our services

At Unplex®, we pride ourselves on our comprehensive approach to product development. We take you through nine distinctive steps, ensuring each phase is executed with precision and strategic insight.

Our comprehensive services cover every phase of product development, making us the ideal partner for your next innovation in medical devices, defense, and industrial automation.

Every groundbreaking product begins with a spark of inspiration. At Unplex®, we collaborate closely with you to refine this spark into a robust product concept. By understanding your vision, target market, and the unique challenges you aim to address, we lay the foundation for a product that not only meets market needs but sets new standards for innovation and usability.

- Industrial design

- User-centric design

- Product aesthetics

- 3D modeling

- Design innovation

- Concept development

- Design prototyping

- Product visualization

- Design optimization

- Market differentiation

- Design strategy

- Design trends

- Human-centered design

- Design for manufacturing (DFM)

The blueprint for success is drawn here. Our system design phase integrates your product concept with technical realities, defining the architecture and system requirements. We ensure that every component - from software to hardware - seamlessly works together, creating a cohesive, efficient system that embodies both form and function.

- System architecture

- System integration

- Scalability planning

- Requirements analysis

- Hardware-software synergy

- System validation

- Modular design

- Interface design

- Systems engineering

- Technical specifications

- System optimization

- Subsystem design

- Cross-functional integration

- Performance engineering

Precision in hardware design is crucial. Our expert team tailors cutting-edge hardware solutions that optimize performance and reliability. From selecting the right processors to designing custom PCBs, we handle the intricacies of hardware development, ensuring your product has the robust backbone it needs to thrive in competitive markets.

- Hardware design

- Electronic circuit design

- PCB layout

- FPGA design

- Hardware prototyping

- Embedded systems

- Analog & digital electronics

- Component selection

- Signal integrity

- Hardware optimization

- Power management

- Hardware testing

- Schematic design

- Microcontroller programming

Durability meets design. In the mechanical design phase, we focus on creating products that are not only robust and reliable but also aesthetically appealing. Our designs take into account ergonomics, materials, and the manufacturing process, ensuring that the final product is both functional and a delight to use.

- Mechanical engineering

- CAD modeling

- Mechanical components

- Structural analysis

- DFM principles

- Thermal management

- Material selection

- Mechanical prototyping

- Tolerance analysis

- Mechanical assembly design

- Kinematics

- Finite Element Analysis (FEA)

- Product durability

- Mechanical testing

Software breathes life into your product. Our agile software development team crafts bespoke solutions, from low-level system software to user-facing applications. By prioritizing user experience and system reliability, we develop software that enhances functionality and ensures seamless interaction between the user and the device.

- Embedded software

- Software development

- Firmware development

- Cross-platform development

- Software integration

- User interface (UI) design

- Software testing

- Software validation

- Software optimization

- Agile development

- Software architecture

- Real-time systems

- Software security

- Code development

Quality begins with the right materials and partners. We meticulously select and source components from trusted suppliers, ensuring that every element of your product meets our high standards for quality and sustainability. This strategic selection process is key to optimizing production efficiency and cost-effectiveness.

- Supplier selection

- Global sourcing

- Supply chain management

- Supplier audits

- Procurement strategy

- Vendor evaluation

- Cost optimization

- Supplier negotiation

- Quality assurance

- Component sourcing

- Supplier relationship management

- Logistics planning

- Risk assessment

- Supply chain optimization

- Materials management

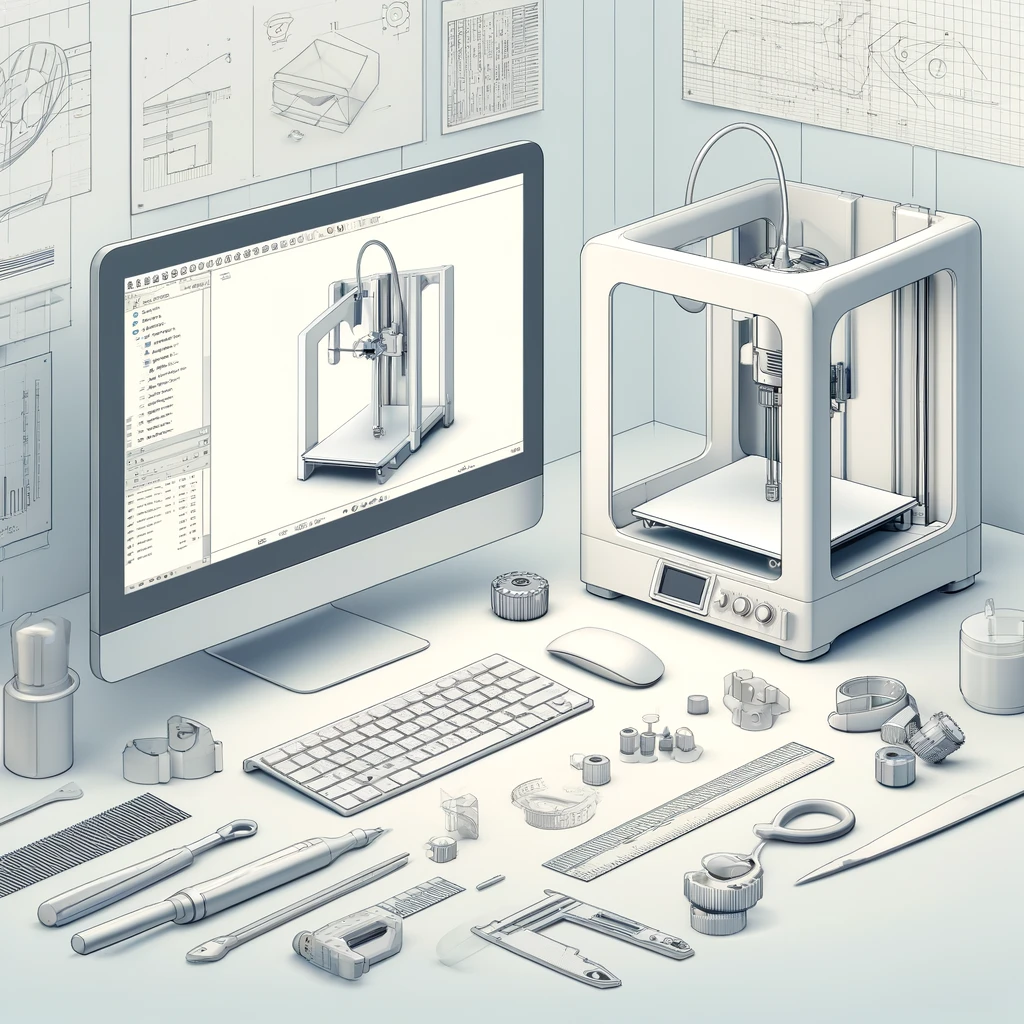

Bringing ideas to reality. Our prototyping and Design for Manufacturability (DFM) phase is where concepts are tested and refined. By creating functional prototypes, we validate the design, functionality, and manufacturability of your product, ensuring that it is ready for mass production without compromising on quality or performance.

- Prototyping

- Rapid prototyping

- Design for manufacturability

- Design iterations

- Prototype testing

- Manufacturability analysis

- Cost optimization

- 3D printing

- Pilot runs

- Production tooling

- Functional prototypes

- Process optimization

- Manufacturing feasibility

- Assembly optimization

- Prototype validation

Rigorous testing ensures impeccable performance. We subject your product to a comprehensive suite of tests, simulating real-world conditions to validate its performance, reliability, and safety. This meticulous validation process guarantees that the product not only meets but exceeds industry standards.

- Compliance testing

- Regulatory compliance

- Certification processes

- Safety standards

- CE marking

- FDA approval

- ISO standards

- EMC testing

- Environmental compliance

- Product certification

- Quality management systems

- Regulatory strategy

- Documentation

- Risk management

- Regulatory submissions

The final leap towards market introduction. In the pilot production phase, we fine-tune the manufacturing process, ensuring that every aspect of production is optimized for quality, efficiency, and scalability. This step is crucial for a smooth transition to full-scale production and market launch.

- Pilot production

- Production planning

- Production monitoring

- Quality control

- Process validation

- Assembly line design

- Yield optimization

- Production logistics

- Supply chain coordination

- Production scheduling

- Manufacturing setup

- Continuous improvement

- Cost-effective production

- Production scaling

At Unplex®, we pride ourselves on our comprehensive approach to product development. We take you through nine distinctive steps, ensuring each phase is executed with precision and strategic insight.

Our comprehensive services cover every phase of product development, making us the ideal partner for your next innovation in medical devices, defense, and industrial automation.